Development history

-

1952

In April, “the Preparatory Office of East China Agricultural Machinery Repair Supply Station” was established. At first, the equipment was only an old belt lathe and a few maintenance tools, mainly to repair the tractors.

In May 1958, it was renamed "Nanjing Agricultural Machinery Factory". In response to the call of the Party to carry out extensive technical innovation, the factory was developed from only repair to general products manufacturing, and then to precision parts, and independently designed and manufactured a full set of fuel pump grinding equipment.

-

1964

In order to resist the former Soviet Union's economic blockade of our country, the factory implemented the spirit of the Central Ministry of Agriculture, "without conditions, we must create conditions", successful independent trial production of Z-35 high pressure fuel injection pump. the company changed from a maintenance station to a manufacturing factory, and its products occupy the agricultural machinery market.

The achievement of “ KD-35 chain track nodular cast iron intermediate test” jointly developed with Tsinghua University fill the gap of our country in this field.

In February 1970, the factory was renamed "Nanjing Tractor Parts Factory".

-

1977

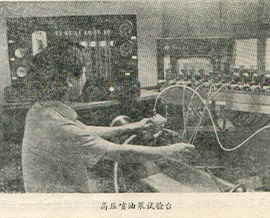

In June 1977, the factory was officially renamed "Nanjing Oil Pump and Nozzle Factory". The annual output of plunger, nozzle and valve exceeds one million sets.

The No. 0 single cylinder fuel injection pump assembly designed and developed by ourselves has identified by national relevant departments and been put into production in large quantities. The result of this initiative fills the blank of our small diesel engine without fuel pump matching.

Subsequently, a variety of variant products have been developed, covering the small air cooled diesel engine market in all provinces and cities in the country, the product accounts for 90% of the total market volume.

-

1988

After the reform and opening-up, the factory made the strategic decision of transforming from single agricultural machinery market to two markets of agricultural machinery and automobile.

In 1985, the factory cooperated with Wuxi Oil pump nozzle Research Institute to develop VE distribution pump for lightweight high-speed vehicle diesel engine, as the world's most advanced high pressure fuel injection pump, it is still blank in China.

In 1988, the factory became the first manufacturer in China to successfully develop VE distribution pump and identified by national relevant departments.

-

1997

.jpg)

Nanjing Oil pump and Nozzle Factory, which used to be a large profit and tax holder in the industry, had an operating loss since 1994.

In 1997, on the basis of the original Nanjing Oil pump and Nozzle factory, "Nanjing Weifu Jinning Co., LTD." was jointly invested by Wuxi Weifu Group Co., LTD. (80%) and Nanjing New engineering Group Co., LTD. (20%) under Nanjing State-owned Assets Supervision and Administration Commission

After experiencing setbacks, Weifu Jinning people grasped the market externally and reform internally. After 3 years, the company turned losses into profits and completely got rid of difficulties and embarked on the track of sound development.

.jpg)

.jpg)

.jpg)

-

2009

.jpg)

The three factories are integrated into Nanjing high-tech Industrial Development Zone, covering an area of 200,000 m², the total construction area of 90,000 m², the production and management of the company is more large-scale.

Independent research and development of electronically controlled high-pressure injection VE pump system to meet the national Ⅲ standard, obtain the "Jiangsu Province scientific and technological achievements transformation of the special fund project" support, quickly realize industrialization, successfully break the monopoly of foreign products.

The company held the first electric control VE distribution pump maintenance training class with more than 300 participants, which greatly improved the external influence of our company's electric control VE pump and other auto parts products.

.jpg)

.jpg)

-

2016

.jpg)

Affected by the official implementation of national Ⅳ emission regulations in January 2015 and other factors, the sales volume of VE/VP pump for vehicle has declined significantly.

In the face of difficulties, the company changed its business concept in time, grasped the opportunity of emission upgrading of off-road construction machinery and agricultural machinery, and did a good job in product R&D and market expansion.

In the first year of the "13th Five-Year Plan" in 2016, the company successfully completed the R&D and industrialization of off-road T3 products. After a short "trough period", the company's main business indicators showed a good upward trend.

.jpg)

.jpg)

-

2020

The company are working together as one to withstand the severe test of COVID-19 and complex market conditions.

——Leading by the core strategy, completed the formulation of the company's "14th Five-Year" strategic plan;

——Focus on operating efficiency, achieved "double growth" for sales revenue and profit, the planned capacity of VE pump broke through 300,000 units, at all-time record high;

——Focus on new industry development, obtained "double breakthrough" for intelligent hydraulic system and vacuum pump;

——Focus on management upgrading, and maintain a good situation of high-quality development and harmony and stability.

1952

In April, “the Preparatory Office of East China Agricultural Machinery Repair Supply Station” was established. At first, the equipment was only an old belt lathe and a few maintenance tools, mainly to repair the tractors.

In May 1958, it was renamed "Nanjing Agricultural Machinery Factory". In response to the call of the Party to carry out extensive technical innovation, the factory was developed from only repair to general products manufacturing, and then to precision parts, and independently designed and manufactured a full set of fuel pump grinding equipment.

1964

In order to resist the former Soviet Union's economic blockade of our country, the factory implemented the spirit of the Central Ministry of Agriculture, "without conditions, we must create conditions", successful independent trial production of Z-35 high pressure fuel injection pump. the company changed from a maintenance station to a manufacturing factory, and its products occupy the agricultural machinery market.

The achievement of “ KD-35 chain track nodular cast iron intermediate test” jointly developed with Tsinghua University fill the gap of our country in this field.

In February 1970, the factory was renamed "Nanjing Tractor Parts Factory".

1977

In June 1977, the factory was officially renamed "Nanjing Oil Pump and Nozzle Factory". The annual output of plunger, nozzle and valve exceeds one million sets.

The No. 0 single cylinder fuel injection pump assembly designed and developed by ourselves has identified by national relevant departments and been put into production in large quantities. The result of this initiative fills the blank of our small diesel engine without fuel pump matching.

Subsequently, a variety of variant products have been developed, covering the small air cooled diesel engine market in all provinces and cities in the country, the product accounts for 90% of the total market volume.

1988

After the reform and opening-up, the factory made the strategic decision of transforming from single agricultural machinery market to two markets of agricultural machinery and automobile.

In 1985, the factory cooperated with Wuxi Oil pump nozzle Research Institute to develop VE distribution pump for lightweight high-speed vehicle diesel engine, as the world's most advanced high pressure fuel injection pump, it is still blank in China.

In 1988, the factory became the first manufacturer in China to successfully develop VE distribution pump and identified by national relevant departments.

1997

Nanjing Oil pump and Nozzle Factory, which used to be a large profit and tax holder in the industry, had an operating loss since 1994.

In 1997, on the basis of the original Nanjing Oil pump and Nozzle factory, "Nanjing Weifu Jinning Co., LTD." was jointly invested by Wuxi Weifu Group Co., LTD. (80%) and Nanjing New engineering Group Co., LTD. (20%) under Nanjing State-owned Assets Supervision and Administration Commission

After experiencing setbacks, Weifu Jinning people grasped the market externally and reform internally. After 3 years, the company turned losses into profits and completely got rid of difficulties and embarked on the track of sound development.

.jpg)

.jpg)

.jpg)

2009

The three factories are integrated into Nanjing high-tech Industrial Development Zone, covering an area of 200,000 m², the total construction area of 90,000 m², the production and management of the company is more large-scale.

Independent research and development of electronically controlled high-pressure injection VE pump system to meet the national Ⅲ standard, obtain the "Jiangsu Province scientific and technological achievements transformation of the special fund project" support, quickly realize industrialization, successfully break the monopoly of foreign products.

The company held the first electric control VE distribution pump maintenance training class with more than 300 participants, which greatly improved the external influence of our company's electric control VE pump and other auto parts products.

.jpg)

.jpg)

2016

Affected by the official implementation of national Ⅳ emission regulations in January 2015 and other factors, the sales volume of VE/VP pump for vehicle has declined significantly.

In the face of difficulties, the company changed its business concept in time, grasped the opportunity of emission upgrading of off-road construction machinery and agricultural machinery, and did a good job in product R&D and market expansion.

In the first year of the "13th Five-Year Plan" in 2016, the company successfully completed the R&D and industrialization of off-road T3 products. After a short "trough period", the company's main business indicators showed a good upward trend.

.jpg)

.jpg)

2020

The company are working together as one to withstand the severe test of COVID-19 and complex market conditions.

——Leading by the core strategy, completed the formulation of the company's "14th Five-Year" strategic plan;

——Focus on operating efficiency, achieved "double growth" for sales revenue and profit, the planned capacity of VE pump broke through 300,000 units, at all-time record high;

——Focus on new industry development, obtained "double breakthrough" for intelligent hydraulic system and vacuum pump;

——Focus on management upgrading, and maintain a good situation of high-quality development and harmony and stability.